But After stood out.

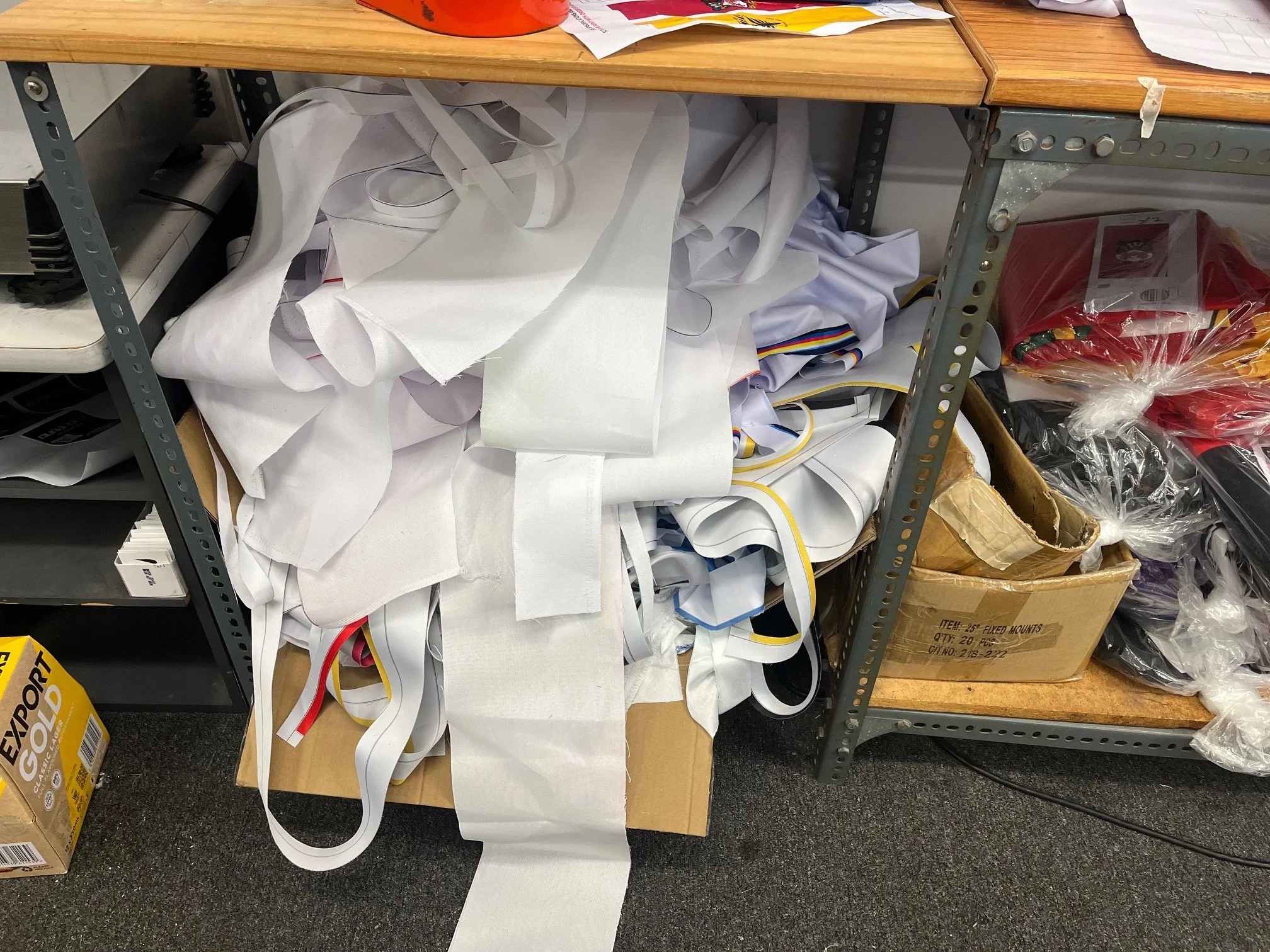

“It’s an easy, accessible, and cost-effective solution. While there is a cost, it’s not high - and it’s offset by savings in landfill fees. More importantly, the environmental benefit is real.”

Interested in starting textile recycling for your business? Get in touch with us - we’d love to help you build a more circular future.

Previous

Previous

A Creative Lens to Textile Waste: After x Collarts at Melbourne Design Week

Next

Next